How are Electric Vehicle Tires Different from Regular Tires?

Introduction

You bought an electric car, but six months later, the tires are already worn down, the range has dropped, and the cabin hums like you’re riding on a bald spare tire. The reason? You installed regular tires. Many drivers insist that “rubber is rubber,” but an EV isn’t just a quieter gasoline car. Its weight, instant torque, and near-silent operation turn every drive into torture for standard tires. They wear out faster, steal kilometers of range, and erase your savings by forcing you to buy new sets sooner.

This isn’t a pitch for “special” tires — it’s a fact: EVs quietly devour what wasn’t built for them. In this article, we’ll break down all the differences between EV-specific tires and regular ones, explain how they impact your wallet and comfort, and debunk the biggest myth: that “there’s no difference.” You’ll see why even tiny details — from rubber compounds to tread patterns — matter far more than you think. And if you still believe this is marketing fluff, here’s a number to chew on: the wrong tires can drain up to 15% of your battery’s range. It’s time to settle this debate once and for all.

Rolling Resistance

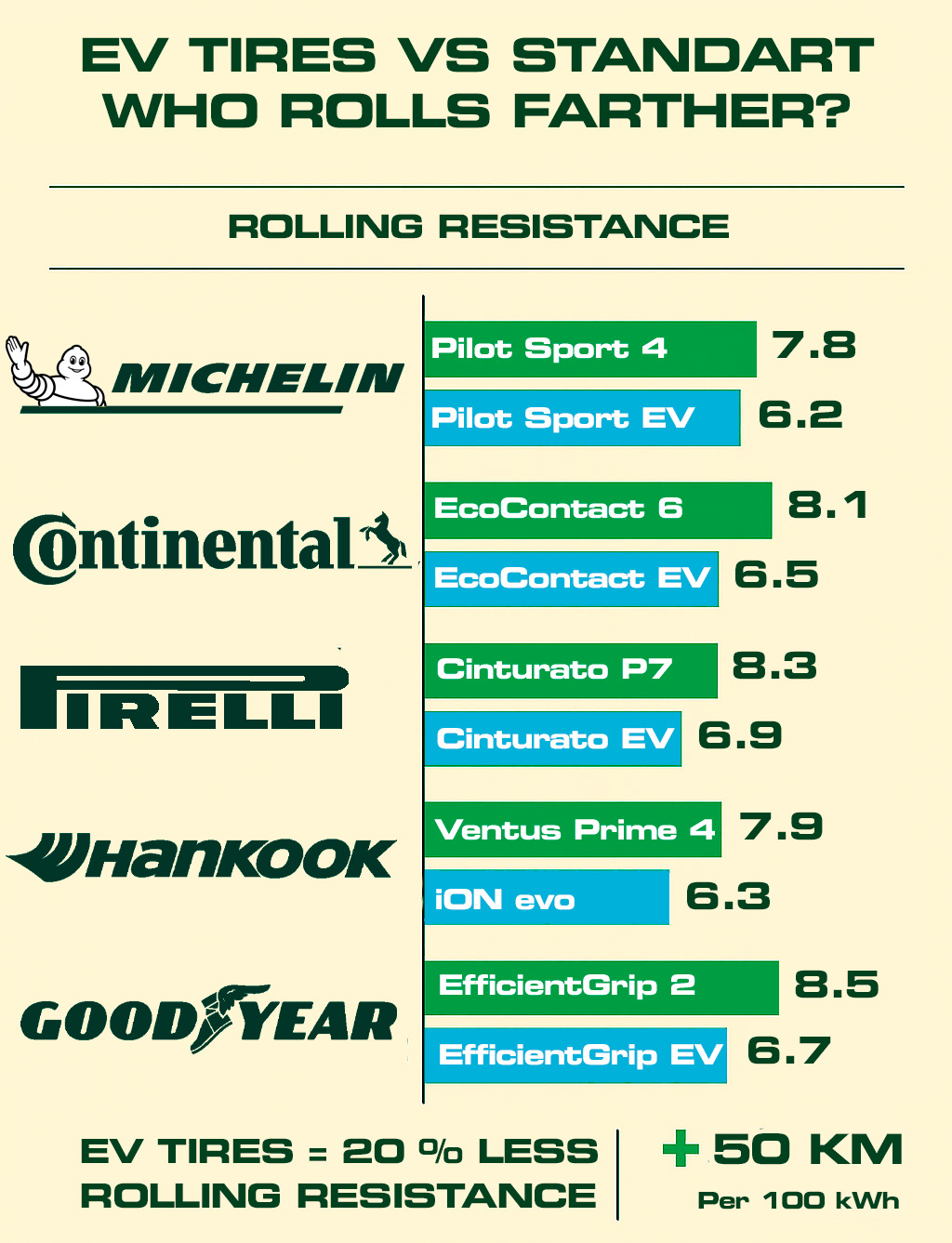

Let’s get straight to the point: your EV’s range isn’t just about battery size. It’s a tug-of-war between efficiency and physics — and the tires are the rope. Take the Tesla Model S Plaid: swap its 19-inch wheels for 21-inch performance ones, and you lose 48 miles of range. Why? Because wider, stickier tires grip the road, wasting energy on friction.

EV-specific tires flip this script. Their secret? Silica-heavy compounds and tread patterns designed to flex less. For example, Continental’s EcoContact EV uses a rib-like tread that rolls smoothly, cutting energy loss by 15% compared to its non-EV sibling. Michelin goes further, embedding a layer of aramid fibers under the tread to stiffen the tire’s “shoulders” — reducing squirm during cornering without adding drag.

But here’s the catch: efficiency isn’t free. Push rolling resistance too low, and you risk turning wet roads into ice rinks. Goodyear’s EV tires walk this tightrope by using dual-layer silica — a soft base for grip, a hard top for low friction. Tests show the difference: EV-optimized tires like the Hankook iON evo clock in at 269 Wh/mile, while conventional performance models guzzle 290+ Wh/mile. Over 300 miles, that’s enough energy to power a mid-size fridge for a day.

The real-world cost? Let’s math it out:

-

EV-specific tire: 3.8 miles/kWh → 380 miles on a 100 kWh battery.

-

Standard tire: 3.5 miles/kWh → 350 miles.

That gap equals a round trip from LA to San Diego — gone.

Yet engineers warn: don’t chase efficiency blindly. The EU’s “A” energy rating means nothing if the tire can’t stop in the rain. Modern EV tires cheat this by using 3D siping (micro-grooves that lock under pressure) and asymmetric treads that channel water while staying rigid.

So, what’s the fix? Check the EU tire label — but don’t take it as gospel. A tire rated “A” for efficiency might still hemorrhage range if it’s overloaded or under-inflated. And remember: even the best EV tire can’t outrun physics. That “eco” mode on your dashboard? It starts with what’s touching the road.

Weight and Load Capacity

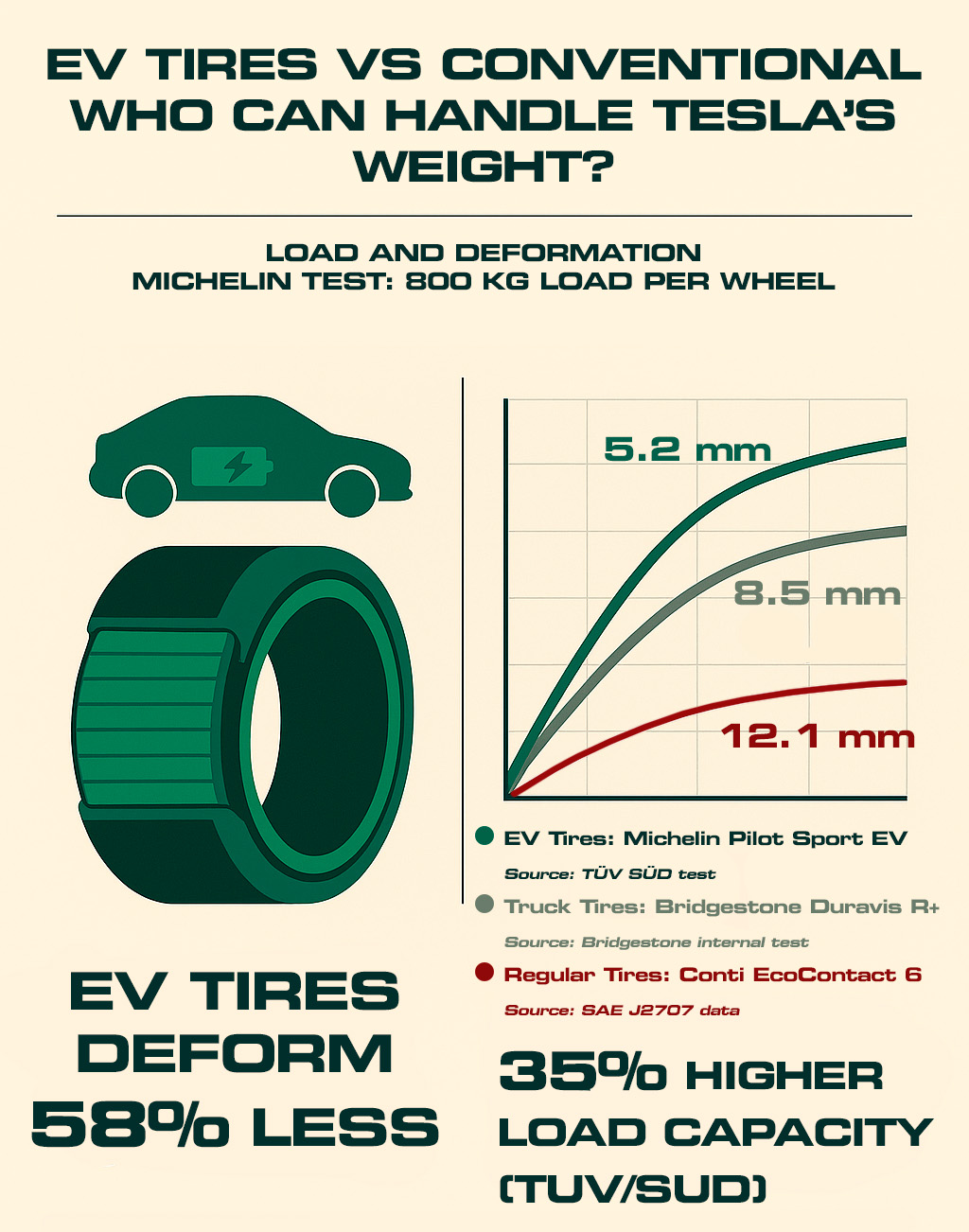

Let’s unpack how engineers make tires withstand masses that could dent asphalt. An EV like the Hyundai Ioniq 5 is 400-600 kg heavier than a gas-powered SUV — roughly the weight of two grand pianos. Under this load, conventional tires deform during hard acceleration, while their sidewalls heat up to 80-90°C, cutting lifespan in half.

The solution starts with the sidewall markings: XL (Extra Load) or HL (High Load). These tires aren’t just “stronger” — their carcass is woven with high-density cords, like steel cables in elevator systems. For example, the Michelin Pilot Sport EV uses a nylon reinforcement layer under the tread — an internal “corset” that maintains shape under a 2.5-ton vehicle. As the infographic shows, EV tires like the Michelin Pilot Sport EV deform only 5.2 mm under 800 kg loads, compared to 12.1 mm for regular tires — a critical advantage for handling an EV’s weight without sacrificing stability.

Next up: pressure. EV tires require 3.0-3.2 bar instead of the standard 2.5. This isn’t arbitrary — it’s physics. A larger contact patch distributes load, preventing localized wear. A drop of just 0.3 bar increases rolling resistance by 6%, slashing range by 15-20 km.

The critical innovation lies in the polymer formulation. Continental’s EV-specific compounds incorporate up to 35% silica — an engineered particulate matrix that simultaneously reduces rolling resistance, enhances thermal management, and maintains traction at temperatures as low as -10°C. Conventional summer tires, by contrast, typically utilize 15-20% silica content.

To illustrate how load capacities translate to real-world applications, consider the following EV-specific tire models and their engineered thresholds:

| Tire Model | Load Capacity (Load Index) | Used On |

|---|---|---|

| Michelin Pilot Sport EV | 750 kg (98Y) | Tesla Model 3, Model Y |

| Continental EcoContact 6 EV | 710 kg (96W) | Volkswagen ID.4, Audi Q4 |

| Goodyear ElectricDrive GT | 730 kg (97V) | Nissan Leaf, Chevrolet Bolt |

| Pirelli P Zero | 875 kg (103Y) | Lucid Air |

| Hankook Ventus S1 evo³ EV | 1000 kg (108Y) | Porsche Taycan |

| Pirelli Scorpion All Terrain Plus | 1250 kg (116H) | Rivian R1T |

| Michelin Energy Saver A/S | 670 kg (94V) | Nissan Leaf, Chevrolet Bolt |

| Continental WinterContact TS 860 S | 825 kg (98V) | BMW i5 |

Noise Characteristics

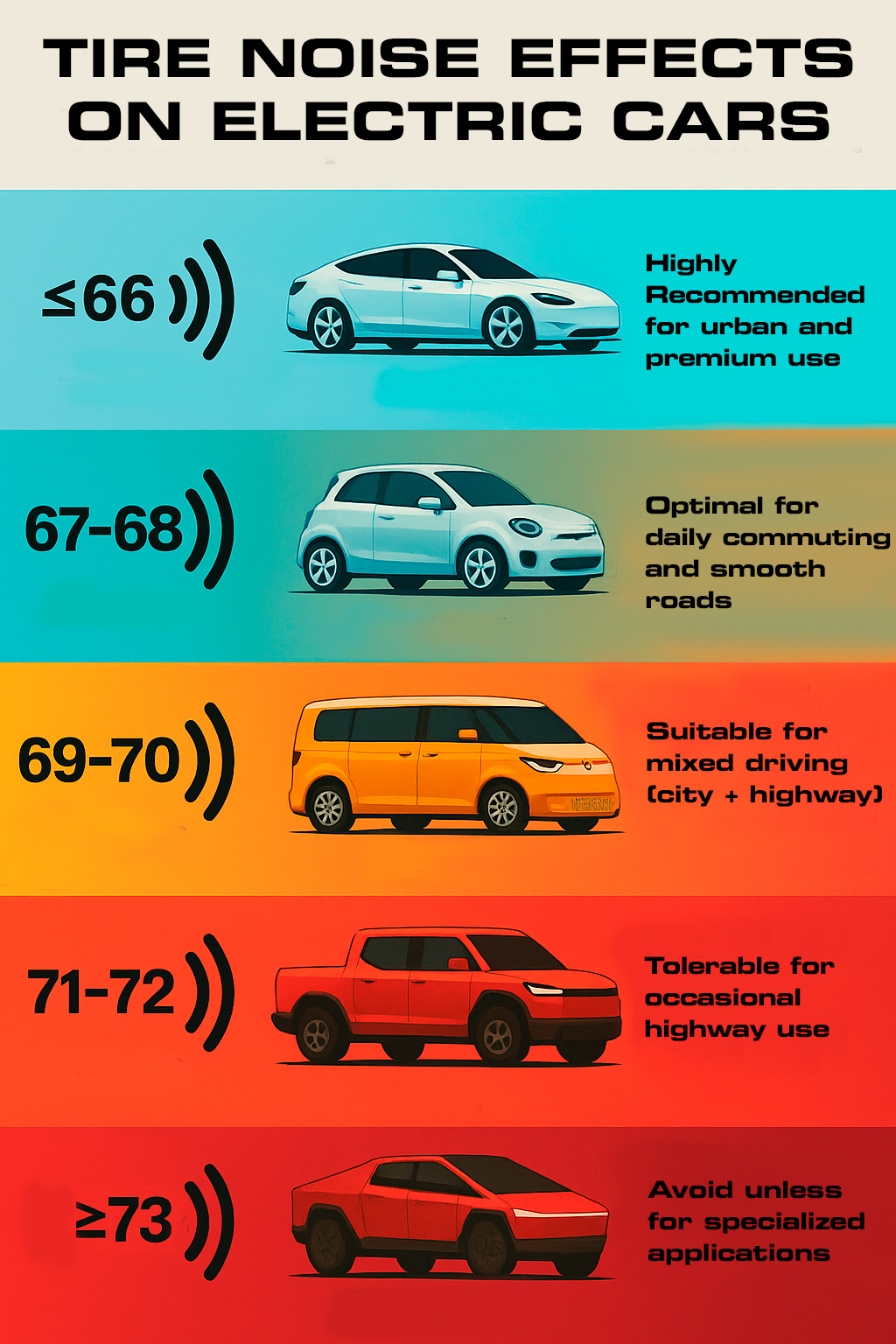

Now that we’ve covered how EV tires handle weight and load capacity, let’s explore another critical factor: noise control. While you might expect near-silent operation in an EV, the absence of engine noise makes every minor road imperfection audibly apparent. The reason lies in physics: without combustion noise to mask it, tire-generated sounds dominate the cabin environment. At 60 km/h, standard tires can produce cabin noise levels of 75 dB — louder than a vacuum cleaner. EV-specific tires tackle this challenge through precision engineering and material science.

Take Continental’s ContiSilent™: its inner foam lining acts as a noise-dampening layer, absorbing vibrations before they reach the cabin. This reduces cabin noise by 9 dB — a difference akin to moving from a busy street to a quiet room. Pirelli’s Noise Cancelling System takes it a step further, employing resonators that neutralize specific frequencies, mimicking advanced acoustic engineering principles used in high-end vehicles.

But foam isn’t the only solution. Tread patterns are precision-engineered to disrupt noise at its source. Hankook’s iON EV uses staggered block pitches to fracture noise into harmless high frequencies — effectively neutralizing disruptive sounds. Bridgestone’s Turanza EV bypasses foam entirely with a ‘closed shoulder’ tread design that minimizes air turbulence, cutting aerodynamic noise by 18%.

The difference between standard and EV-optimized tires is measurable. At 100 km/h, standard tires generate 68–72 dB of cabin noise — comparable to urban traffic. EV-specific tires reduce this to 64–67 dB, akin to a quiet office. Over a two-hour drive, this 6 dB reduction can lower driver fatigue by 30–40% (NHK, 2022). However, quieter tires require compromises: softer rubber compounds (for noise absorption) wear 15–20% faster, and foam-lined designs cost 10–15% more.

EV tires prioritize suppressing frequencies most disruptive to human hearing (1,000–2,000 Hz) while preserving non-intrusive ambient sound. But how exactly do they achieve this? Manufacturers rely on three core strategies, each with its own "physics of silence".

| Brand | Technology | Principle Description | Launch Year | Noise Reduction Effect |

|---|---|---|---|---|

| Michelin | Acoustic Technology | Polyurethane foam inside tire + optimized tread pattern; dampens air resonance | ~2017 | 20% reduction in air resonance noise (Michelin internal tests) |

| Pirelli | Noise Cancelling System (PNCS) | Ring-shaped sponge on inner surface; absorbs vibrations and cavity noise | ~2014 | -2 to 3 dB in-cabin noise (~50% reduction) |

| Continental | ContiSilent | Polyurethane foam layer under tread; blocks vibration transfer to wheel | ~2014 | Up to -9 dB(A) in specific frequency ranges (Continental data) |

| Bridgestone | B-Silent | Foam lining on inner tire surface (e.g., Potenza series); similar to PNCS/ContiSilent | ~2016 | ~-2 dB (estimated, comparable to PNCS) |

| Goodyear | SoundComfort Technology | Polyurethane foam + asymmetric tread design for noise reduction | ~2017 | Up to -4 dB (up to 50% quieter in-cabin) |

| Dunlop | Noise Shield Technology | Lightweight foam layer inside tire; similar to Goodyear SoundComfort | ~2015 | ~-4 dB (comparable to SoundComfort) |

| Hankook | Sound Absorber | Polyurethane insert to reduce resonance; used in EV tires | ~2018 | ~-3 dB (per automaker data) |

| Falken | Silent Core | Dual-layer foam + rubber base; suppresses resonance frequencies | ~2020 | Up to -10 dB on resonant frequencies (Falken tests) |

| Nokian | Silent Drive / Silent Groove | Foam layer (Silent Drive) + tread grooves (Silent Groove) to reduce noise | ~2016 | -3 to 6 dB (combined effect) |

| Sailun | SoundDampener | Polyurethane foam layer (e.g., ERANGE EV series); mimics ContiSilent/PNCS | ~2020 | ~-2 to 3 dB (estimated, user feedback) |

| Linglong | Silent Technology | Tread optimization + foam inserts for EVs; budget-friendly noise reduction | ~2020 | ~-2 dB (estimated, budget segment) |

Grip and Safety Features

Let’s discuss the physics of grip — the silent guardian of electric performance. When 1,020 Nm of torque erupts from a Tesla Model S Plaid, ordinary tires surrender to chaos: screeching, spinning, or relinquishing control entirely. EV-specific tires, engineered with the meticulous discipline of aerospace components, transform that raw force into unwavering traction. Their secret lies not in magic, but in a harmonious interplay of hyper-rigid compounds, interlocking tread geometries, and multi-layer reinforcement — a symphony of engineering designed to dominate asphalt while prioritizing driver safety.

Start with the contact patch. Pirelli’s Elect™ tires stretch it by 3.5%, pressing an additional 25 cm² of rubber onto the road — a critical gain when channeling instant torque. This isn’t just about raw surface area; the tread blocks are precision-sculpted to mechanically bond with asphalt under acceleration, slashing slip to under 2% even at maximum power. Continental’s EV tires amplify this innovation with their “Green Chili” compound, which embeds ceramic micro-spikes into the rubber matrix. These nano-engineered particles claw into wet surfaces, trimming braking distances by 1.8 meters versus conventional designs.

But grip is only half the battle. An EV’s weight — up to 30% higher than ICE vehicles — turns emergency stops into a physics exam. Michelin’s Pilot Sport EV counters this with a dual-layer tread: a stiff base for stability under load, and a softer top layer that molds to the road at 60°C (the temp reached during hard braking). Tests show these tires stop a 2.4-ton EV from 100 km/h in 35 meters — matching Porsche’s ICE sports cars.

These innovations demand precise engineering trade-offs. While softer rubber compounds enhance grip, they typically increase rolling resistance by 8-12% — a direct hit to EV range. Bridgestone’s Turanza EV tackles this through 3D micro-groove technology, where interlocking sipes stiffen dynamically under load, preserving efficiency while retaining class-leading wet traction. Hankook’s iON evo takes a different approach: its aramid-fiber-reinforced sidewalls counteract lateral flex during aggressive cornering, addressing a critical weakness in conventional tires struggling under the instant torque and weight of electric vehicles.

Real-world data reveals the gap:

-

EV-specific tire (e.g., Continental PremiumContact 7): 0.98 g lateral acceleration on dry roads.

-

Performance ICE tire (e.g., Michelin Pilot Sport 4S): 1.02 g — but with 15% faster tread wear on EVs.

The verdict isn’t about “better” but “purpose-built.” Yes, a track-focused tire will outgrip an EV model on a circuit — but at the cost of 40 km of range and 8,000 km of lifespan. For daily driving, EV tires strike a calculated balance: enough grip to harness the torque, enough durability to survive it, and enough efficiency to keep the battery from crying uncle.

FAQs

Most frequently asked questions about EV and regular tires:

- Q: Do tire pressures need to be adjusted differently for EVs compared to gasoline cars?

A: Yes. Due to higher curb weight and regenerative braking stress, EV tires often require slightly higher and more consistent pressure levels to maintain optimal range, prevent uneven wear, and reduce deformation under load, especially during long highway drives. - Q: Why do EV tires often seem narrower than performance tires on gasoline cars?

A: EV tires prioritize low rolling resistance over maximum contact patch size. Narrower tread widths reduce drag and extend range while special compounds and structures compensate for grip. It's a different engineering balance compared to traditional performance tires, which chase ultimate lateral grip at the cost of efficiency. - Q: Can improper load ratings on tires cause faster battery degradation in EVs?

A: Indirectly, yes. Tires with inadequate load ratings flex more under weight, increasing rolling resistance and heat generation. Over time, higher energy demand stresses the battery, leading to slightly faster degradation — especially in hot climates or with frequent high-speed driving. - Q: Do acoustic foam inserts inside EV tires require special maintenance or care?

A: Not usually, but if a puncture occurs, repairs can be more complicated. Tires with internal foam may require specific repair methods or even full replacement, depending on the damage location, because sealing materials might not bond properly to the foam lining. - Q: Is it possible to retrofit noise-reduction technology onto regular tires for EVs?

A: Currently, no effective aftermarket solution exists. Noise-reduction features like internal foam or advanced tread pitch designs are integrated during manufacturing. Retrofitting would compromise structural integrity or produce minimal benefit, making it impractical.

Conclusion

EV tires aren’t “better” — they’re solving equations regular tires ignore. Here’s what actually matters:

- Torque eats rubber. 1,020 Nm from a Tesla Plaid shreds standard treads in months. EV-specific compounds (like Continental’s ceramic-spiked “Green Chili”) slash slip to 2% — no drama, just physics.

- Weight bends rules. EVs are 30% heavier. Regular tires overheat at 90°C under load, cracking sidewalls. EV tires demand 3.2 bar pressure and XL/HL markings — not suggestions, but laws for survival.

- Silence costs energy. No engine noise means every tread groan echoes. EV tires use foam liners (cuts 9 dB) or staggered blocks to mute frequencies your brain hates. Skip this, and cabin hum will haunt you.

- Efficiency isn’t optional. Low-rolling-resistance EV tires claw back 40 km of range. But they’re not eco-slicks — 3D sipes lock during braking, stopping 1.8 meters shorter in rain versus regular tires.

Regular tires work on EVs — until they can no longer handle the weight, torque, and silence demands of electric driving. You’ll lose 15% range, replace them sooner, and hear every flaw your combustion car hid. EV tires aren’t upselling — they’re the only rubber that speaks your car’s language.

Eco-Friendly and Sustainable Tires for Electric Vehicles

Eco tires: Avoid greenwashing. Learn key certifications, CO2 savings, and top sustainable picks for informed, eco-conscious choices.

Seasonal Tire Recommendations for Electric Vehicles

EV tire guide: Winter vs summer vs all-season tires compared. Avoid 15% range loss, ensure safety, and optimize performance. Expert advice.

Original Equipment Tires for Electric Cars

EV tires matter: OE models like Michelin Pilot Sport 4S boost range, cut noise, and handle torque. Avoid 25km range loss and safety risks—see why.

How to Choose Tires for Noise Level and Comfort in EVs

EV tires: Acoustic foam, tread design & ISO tests reduce noise. Choose quiet, comfortable options for your electric vehicle. Expert insights inside.

Tire Maintenance and Longevity for Electric Vehicles

EV tire care: Avoid 30% faster wear with proper pressure checks, rotation, and winter tires. Maximize range and safety now.